PROLUNGHIAMO LA VITA DEGLI IMPIANTI

CON TRATTAMENTI ANTI-CORROSIVI

E RINFORZI STRUTTURALI

–

CON TRATTAMENTI ANTI-CORROSIVI

E RINFORZI STRUTTURALI

–

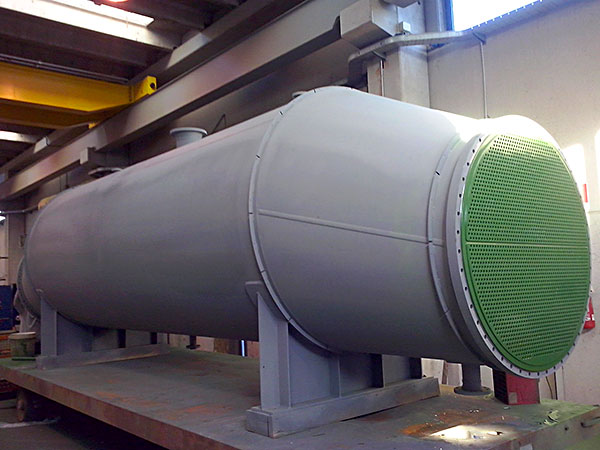

GMA è lo specialista nella riparazione e manutenzione su tubazioni, scambiatori di calore serbatoi, vasche e attrezzature varie. Dal 1987 operiamo a fianco delle principali aziende del settore Oil & Gas, Energetico e Chimico prolungando la vita degli assets e ripristinando le condizioni ottimali di funzionamento, nel rispetto della sostenibilità e della sicurezza.

COSA POSSIAMO FARE PER TE?

Riparazione

Mettiamo il cliente al centro delle nostre attività. Forniamo soluzioni tecnicamente innovative e personalizzate ad ogni tipo di rottura. Rispondiamo con rapidità alle richieste di intervento, con la massima qualità dei risultati e nel rispetto per l’ambiente.

CORROSIONE

–

I nostri esperti riparano in modo mirato le superfici danneggiate e corrose, assicurando la sicurezza e l’efficienza a lungo termine.

Scopri le nostre soluzioni anticorrosive

Depositi

–

–

Lavoriamo per eliminare i depositi utilizzando tecniche avanzate per ripristinare le condizioni ottimali di funzionamento.

Scopri le nostre soluzioni di lavaggio

PERDITE E FUORIUSCITE

–

Ripariamo i danni e implementiamo soluzioni preventive per evitare futuri incidenti.

In caso di emergenza interveniamo rapidamente per minimizzare i rischi per l’ambiente e la salute e per ripristinare il funzionamento degli impianti.

In caso di emergenza interveniamo rapidamente per minimizzare i rischi per l’ambiente e la salute e per ripristinare il funzionamento degli impianti.

Scopri le nostre soluzioni

di rinforzo strutturale in fibra di carbonio

prevenzione

Vuoi garantire la produttività del tuo impianto, nel rispetto delle normative sulla sicurezza e con il minor impatto ambientale possibile?

Alcuni dei nostri clienti

–

IL NOSTRO IMPEGNO

PER UN FUTURO SOSTENIBILE

«Costruiamo insieme, passo dopo passo, un futuro migliore.»

CULTURA DELLA SICUREZZA

Proteggiamo le nostre persone

e i tuoi impianti

e i tuoi impianti

Consideriamo le persone il punto di partenza e il fine ultimo di ogni nostra azione.

Per questo ci impegniamo a garantire la sicurezza di tutti i nostri collaboratori con uno sforzo comune e condiviso che contribuisce al mantenimento degli standard.

Alla base di tutto vi è una consolidata cultura della sicurezza e la diffusione del suo valore imprescindibile fra dipendenti, contrattisti e stakeholder locali.

Per questo ci impegniamo a garantire la sicurezza di tutti i nostri collaboratori con uno sforzo comune e condiviso che contribuisce al mantenimento degli standard.

Alla base di tutto vi è una consolidata cultura della sicurezza e la diffusione del suo valore imprescindibile fra dipendenti, contrattisti e stakeholder locali.

News

–