–

–

Our patented technology for the inner coating of tube bundles ensures the application of an even layer of product with a consistent thickness inside the pipe, even in applications more than 10 metres long, and in “U” shaped pipes, too.

Our services are provided by highly qualified and certified personnel, capable of restoring the initial condition of all parts, even the most complex equipment (inner pipe surfaces, tube plates, water boxes, conduits, etc.).

Thanks to our advanced equipment, we have been providing on-site services at our clients’ plants for years, significantly reducing the cost and risk of transportation while also ensuring prompt intervention.

A service performed directly at the client’s premises to nip the problem in the bud, cutting down intervention times and addressing difficulties head on, to face the future with confidence.

PHENCOTE FOR HEAT EXCHANGERS AND SURFACE CONDENSERS

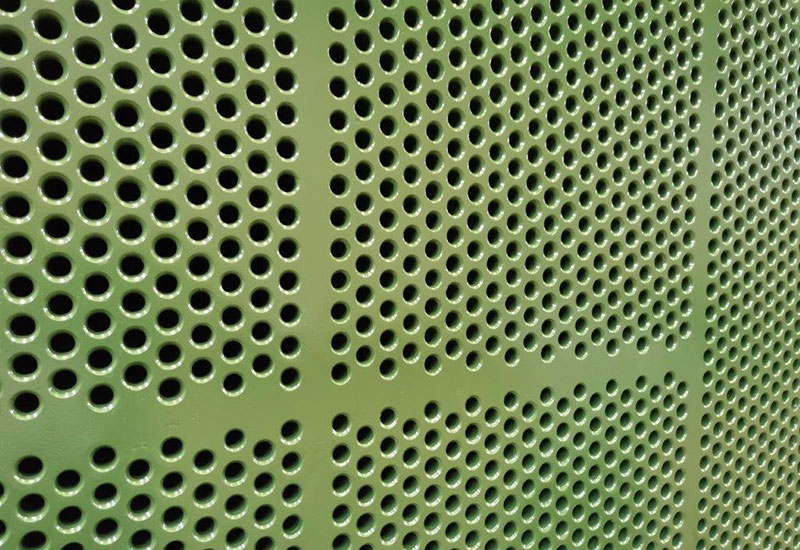

GMA owns the Phencote brand, consisting in a range of epoxy, epoxy-phenolic and phenolic coatings and resins suitable and tested for the most demanding operating conditions. Phencote cycles are employed and recommended by the world’s most renowned refineries, petrochemical plants and energy producers. GMA’s Phencote-based solutions are both competitive and efficient, adapting to all conditions of use to continuously offer the perfect product suited to client needs.

–

Do you work in plants where chemicals, processes and environmental conditions affect the metals and surfaces of your equipment?

Would you like to prevent future repair and restoration costs and extend the service life of your systems?

–

WHY CHOOSE OUR ANTI-CORROSION MAINTENANCE?

–

The prevention and repair of corrosion phenomena offers numerous benefits:

The service life of the system is extended and optimal operating conditions are restored

The service life of the system is extended and optimal operating conditions are restored

Operating and spill risks are reduced, preventing leaks in tube expansions and pipes

Operating and spill risks are reduced, preventing leaks in tube expansions and pipes System downtime is minimised with the possibility to repair running systems

System downtime is minimised with the possibility to repair running systems The repair of piping with complex bends and shapes, and hard-to-reach areas

The repair of piping with complex bends and shapes, and hard-to-reach areas No added weight thanks to lightweight solutions without the need for boxes and scaffolding

No added weight thanks to lightweight solutions without the need for boxes and scaffolding Cost savings, reducing the number of future repair and cleaning operations

Cost savings, reducing the number of future repair and cleaning operations