Anti-corrosion treatment interventions on the TV2 steam condenser

Introduction to the Project

The importance of maintenance

Project phases

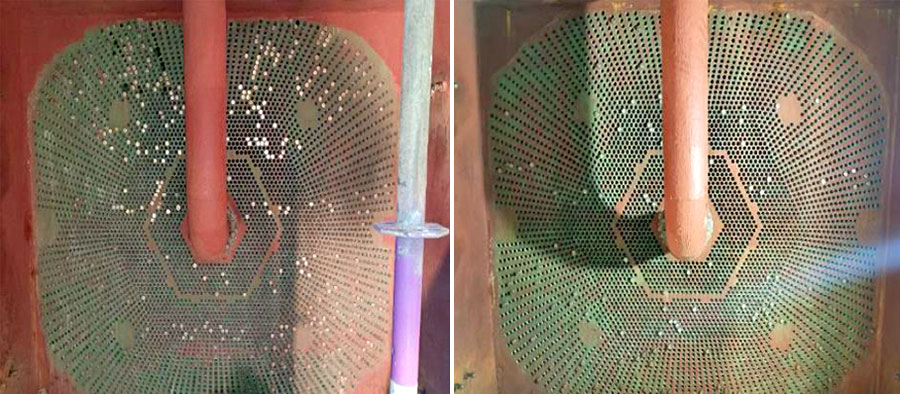

Surface preparation

- Removal of the water tank doors to access the surfaces to be treated.

- Use of probes of different lengths to ensure thorough cleaning.

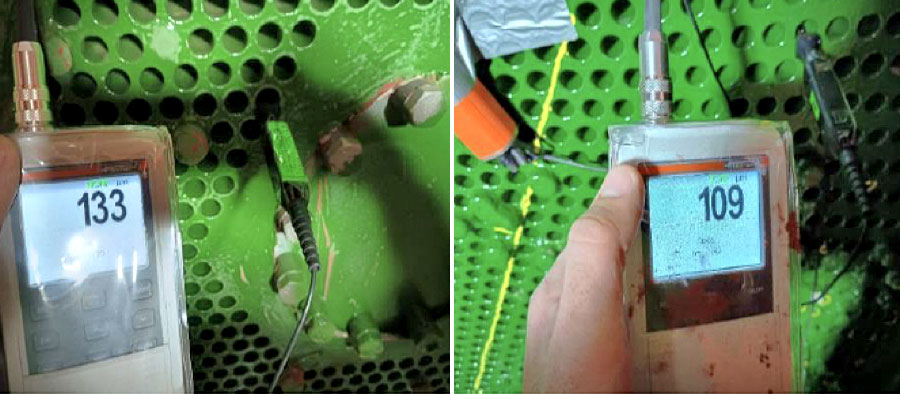

The sandblasting results were evaluated using Testex Coarse in accordance with ISO 8503/5, with roughness values between 30 and 40 microns, thus ensuring adequate preparation.

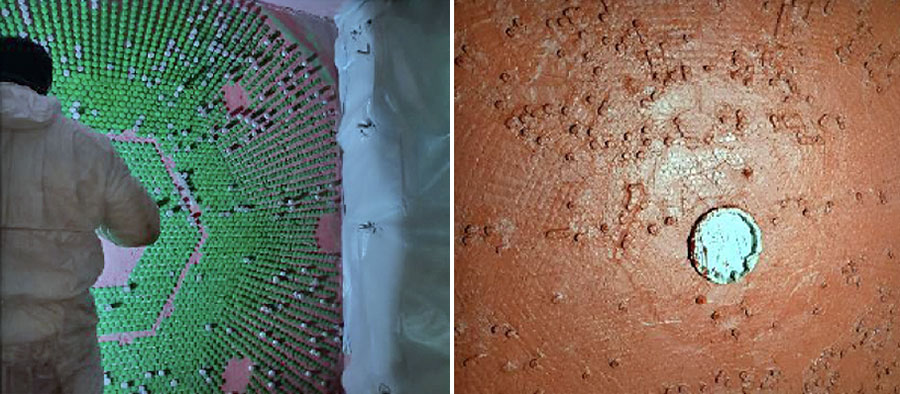

Application of the coating

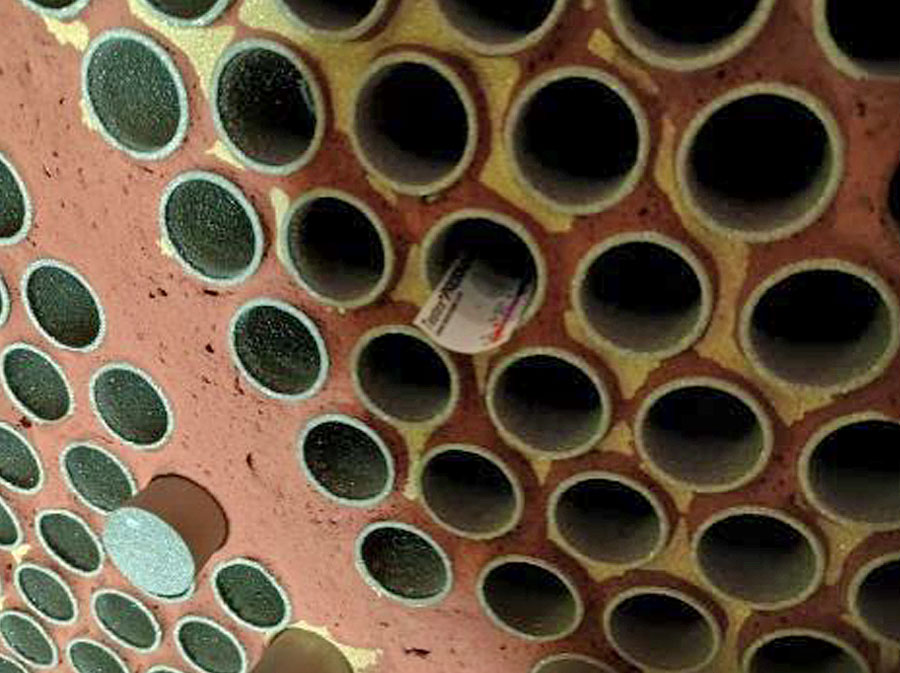

- Internal piping

- Tubular plates

- Water tanks

This phase was monitored by NACE and INAC certified inspectors, ensuring that quality standards were met. The choice of this coating was not random: Phencote HR60TL offers effective protection against corrosion while reducing the degree of accumulated dirt thanks to a less rough surface.

Monitoring and control

Results and benefits

- Reduction in plant downtime: thanks to the protection provided by the coating, a significant reduction in corrosion risks is expected, thereby reducing plant downtime for maintenance.

- Increased installation longevity: anti-corrosion treatment interventions can extend the service life of equipment, enabling a faster return on investment.

- Improved safety: corrosion protection helps to ensure a safer working environment by reducing the risk of accidents related to structural failures.

Conclusion: anti-corrosion treatment is essential

GMA, with its technical expertise and practical approach, is able to tackle the challenges of corrosion with real, concrete solutions.

Our mission is clear: to provide our customers not only with results, but also with peace of mind. With GMA, facilities are not only maintained, but optimised to meet the challenges of the future.

Do not delay protecting your equipment

For more information about our solutions and services, visit the CORROSION section and find out how we can help you protect and optimise your installations.

Renovation of the hexane tank roof: the GMA solution for a safe and reliable structure

Renovation of the hexane tank roof: the GMA solution for a safe and reliable structure The industrial sector is constantly evolving, and structural safety must be a top priority. In this context, GMA stands out for its ability to tackle complex problems with concrete...

Industrial corrosion: how much is it costing your company (and how to stop it before the next shutdown)

Industrial corrosion: how much is it costing your company?The problem that no one sees until it's too lateLet's be clear: as you read this article, your metal structures are losing value. This is not alarmism, it is chemistry. Corrosion does not respect work shifts,...